Military Cable Specifications - For defense projects, the instructions are often very specific. But how do you make sure the cables fit well with other parts of your project? After all, every project is different, so is the construction of related cables (sonar). To answer this question, it is important to know how the design process works. What factors determine the quality of submarine cable construction? What parameters are important for your particular project? Each marine system requires a different cable structure, so your specific requirements are translated into a fit-for-purpose design. In this page, we will explain how cable specifications work in defense projects.

A sonar cable is a complex structure, but it can be divided into several basic and often repeated elements: element - load transfer

Military Cable Specifications

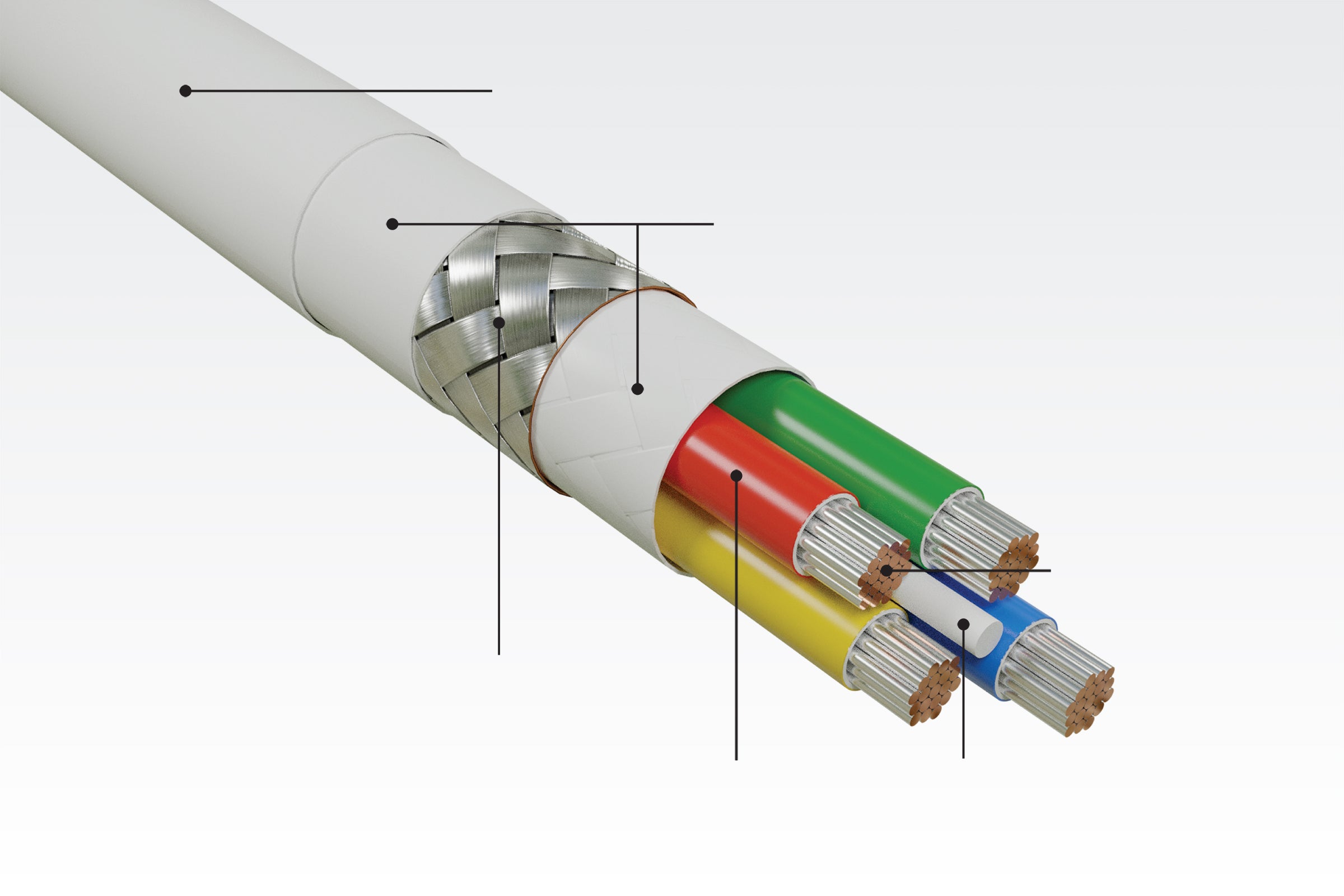

Sensitive components such as electrical and optical components are placed in the core of the audio cable to break down the resistance. A strong member is wrapped around the core. The cable is designed so that the load is not transferred to the components, but through the strong material. This means that the electrical element is designed to save the electrical core that fails first.

Shop For Mil Spec Wire & Cable At Allied Wire & Cable

Another important aspect of sonar string construction is the helical structure. The pieces are arranged in a helix, and tapes and covers separate the layers. The helical structure allows the cable to be bent and stretched without permanent damage to the electrical and optical components. The process of connecting the circuit components is called 'cabling'.

Apart from connecting the cable, only one method is necessary to create the audio cable: extrusion. An insulating layer is applied to the tablet and the cable is sheared.

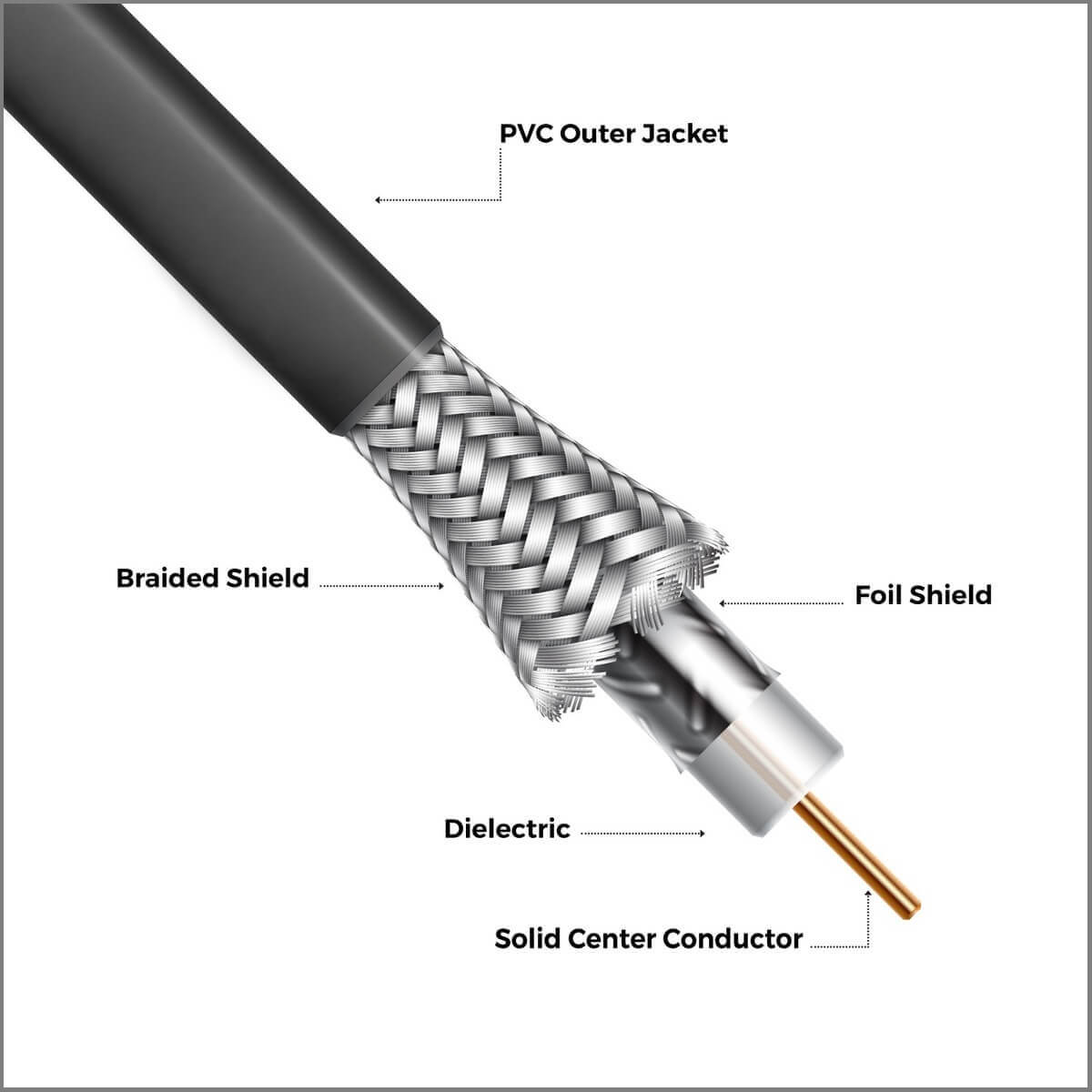

A third method used to construct sonar cables is braiding, but not all cables require this method. This braid is often used to strengthen the sheaths or protect electrical components (in this case, copper braid is used). Sometimes the braid is used as a strong member. This happens when the installed load is small and the elasticity is high. The braid provides a perfect balance of rotation, which may be necessary in some cases.

Requirements are fundamental to the design of any cable system. The main requirements for the definition of defense technology can be divided into five categories: 1. Implementation 2. Operation 3. Operation 4. Environment 5. Interface.

Carol M29184/2 01 Mil Spec Cable Assembly 50'

These requirements are often directly related to physical characteristics. For example, the depth of use directly affects the length of the cable. Density is often an important performance requirement for audio cables. While heavy towed cables must be heavy and therefore contain steel reinforcing material, submarine sonar towed cables and variable depth light towed cables must be as close as possible to the density of water, so they make them neutral.

Other examples of functional requirements are fiber optic requirements such as energy requirements (voltage and current ratings) and bandwidth. These characteristics determine the type, size, and number of components and how they are assembled, and have a significant impact on the geometry of the audio cable.

All these terms are valid. To produce the connecting cable, our experts must know the pulling load, the number of turns, the speed of the vessel and the working depth. Typically, service life data gives the actual design life or time between failures. Changes in speed and depth cause changes in load, and waves and ship motion cause bending loads.

It is important to know the required operating loads, as they determine the maximum work of the cable and directly affect the required strength. The maximum working load is determined by the load required to stretch the cable by 0.6% (further stretching causes permanent deformation of the parts). Often, the strength of the cable is determined by the maximum working load.

White Paper: Hipot Testing Of Military/aerospace Interconnect Components

In military applications, safety is an important requirement for operational sound systems. This shows that the cable can be subjected to high loads without reducing the performance of the cable to an unacceptable level. For most cables, this strain corresponds to a strain of 0.8% to 1%. Normally the cable cannot be subjected to that load more than 5 or 6 times.

Before designing the cable system (sonar), it is important to know the details of the coordinate system. Examples of construction requirements are winch, wheel rim, and hook size. The radius of the loading equipment directly affects the minimum cable bending required.

Other examples of regulatory requirements include deployment, recovery load, and number of launches. Steel is often the logical choice when loading and unloading are heavy.

Handling requirements are usually not verified by testing, so they are always done through a qualifying test.

Syde 5 Ft. Flexible Metal Sync Charge Cable Micro Usb

Defense market specifications are often filled with environmental requirements. These are the necessary conditions for operations in certain areas, for example the Black Sea. It is often related to temperature and chemical resistance and often meets international standards.

You can perform more complex and expensive tests to verify these environmental requirements, but this is usually not necessary. Our suppliers have already carried out environmental tests on the products used in the cables, to show more through analysis. They have already tested the temperatures and chemicals their products can withstand. The products we use for cables and terminations are typically suitable for temperatures from -40°C to 85°C, meeting almost any temperature requirement.

Interface requirements are the requirements for how cables connect to other components. They describe what the termination will look like. The conclusion consists of four main parts.

● At the end of the force member, the load is transferred from the cable force member to the end.

M27500 22sd2t14 Mil Spec Areospace Wire (1836ft)

● Water sealing consisting of various types of seals to protect cables and stop water ingress.

The connector connects directly to your system and is the most important part of the interface and is tightly integrated.

Are you afraid of missing cable specifications that are critical to the success of a defense project? This is not surprising given the number of components an engineer needs to know. To help you out, our wiring experts have created a Technical Guide checklist. Download a free technical editorial list here

Establishing a clear design process creates clarity and structure. This ensures that you can always review and stick to your instructions. Our designers use a five-stage design process to better document progress, each with a review moment: 1. Early design phase 2. Design stages (detailed design and design analysis) 3. Production stage (build , test) Continuous improvement

Legrand On Q 100 Ft Cat 6 Blue Ethernet Cable Coil In The Ethernet Cables Department At Lowes.com

Preliminary Design Phase The preliminary design phase focuses on defining requirements. Based on these, conceptual models were developed. A Model Conformance Matrix (DCM) is developed which lists the verification process for each requirement. It tells you how to make sure each requirement is met. According to DCM, the qualification test plan and the items to be tested as part of the Factory Acceptance Test (FAT) are defined. At the end of this phase, during the preliminary design evaluation, specifications and concept designs are reviewed and a concept is selected. Then freeze the instructions.

Critical Design Phase During the critical design phase, a detailed design is made and specifications for the sub-components are written. In Critical Design Review (CDR), various designs are evaluated along with specifications. The design has been refined and all parts are ordered for prototype production.

The Prototyping Phase (Building and Testing) The production phase, commonly known as building and testing, is also known as the Test Preparation Phase. Writes detailed instructions and test procedures, designs test equipment, and makes test models. During the Test Readiness Assessment, the test procedures are carefully scrutinized. After this test, the qualifying test can begin. This phase concludes with a functional and physical design audit, and reviews test specimens, test procedures, and test results. The production phase begins only when the prototype passes all tests and meets all specifications. Read more about testing and certification

Production phase All complete production documents for the cable system are produced. These production and production readiness documents are evaluated in the Production Readiness Review. After that, the Production phase involves creating the first article and optimizing the first version. After construction, another test is performed to resolve all inconsistencies and ensure that all requirements are met. After we pass this test, we talk about quality design - it means design